PREMUS 2025: 12th International Scientific Conference on the Prevention of Work-Related Musculoskeletal Disorders

PREMUS 2025: 12th International Scientific Conference on the Prevention of Work-Related Musculoskeletal Disorders

Physical exposure assessment in automobile industry: insights toward efficient dataprocessing and export using XSENS MVN software

Text

Introduction: Physical exposure assessment is commonly performed in industrial settings to prevent musculoskeletal disorders. In occupational settings, time-efficient data collection and analysis are essential for evaluating human movement without disrupting work processes. Reducing the required inputs simplifies the setup and shortens measurement time, which is particularly valuable in fast-paced or time-constrained environments. This study aims to evaluate a simplified XSENS approach using standard-definition export and two anthropometric parameters to reduce computational load without compromising biomechanical accuracy.

Methods: Fifteen automotive assembly workers (age: 36.5 years, seniority 9 years, height: 180 cm, weight: 86 kg), participated in this study. They worked during a 15-minute period of time while wearing 17 IMU sensors (Movella, Enschede, The Netherlands) at 60 Hz. Following the data collection, their 3D kinematics (22 joints– EULER XYZ) were calculated under two conditions: a) using two measured anthropometric parameters (body height and shoe length) while estimating the remaining measures, and b) using 11 measured parameters (body height, shoe length, shoulder height, shoulder width, elbow span, wrist span, arm span, hip height, hip width, knee height, and ankle height). The 3D kinematics were exported in both normal and high-definition (HD) quality on XSENS MVN (v. 2024.2). Mean Absolute Error (MAE) and Relative Error (%) were calculated to assess the differences between Normal-quality using 2 parameters (SD2) vs Normal-quality using 11 parameters (SD11) and HD quality using 11 parameters (HD) vs SD11 across anatomical planes and individual joint angles.

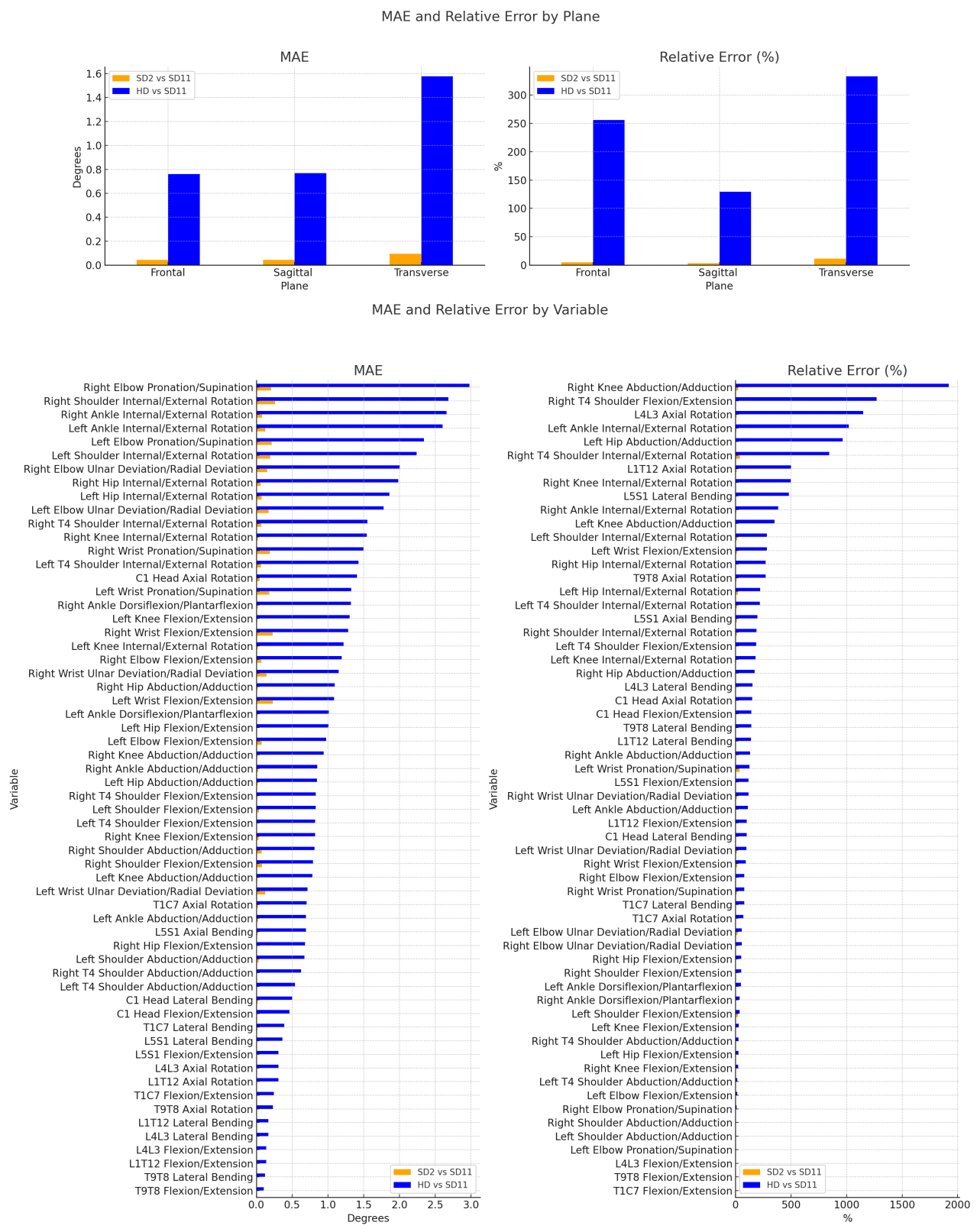

Results: SD2 vs SD11 showed minimal error across all planes, with MAE < 0.1° and Relative Error < 15% (Figure 1 [Fig. 1]). In contrast, HD vs SD11 showed notably higher errors, particularly in the transverse plane (MAE > 1.5°, Relative Error > 300%). SD2 vs SD11 resulted in low errors for most joints, with MAE < 0.1° and Relative Error typically < 5%. HD vs SD11 showed elevated errors in several upper-limb joints, especially in shoulder and wrist rotations where Relative Errors exceeded 100%.

Figure 1: MAEs and Relative Errors for different planes and joints

Discussion: The SD export condition introduced larger discrepancies, particularly in upper-limb joints and the transverse plane, and the key concern is whether such deviations could influence ergonomic scoring systems like REBA. Variables critical to REBA showed low maximal errors under SD. Depending on the movement context and REBA thresholds, such deviations could potentially lead to score misclassification.

Conclusion: These findings support the use of HD export for reliable ergonomic analysis, while highlighting that SD may introduce distortions that could impact posture-based scoring systems like REBA.

Acknowledgements: This work was supported by Fundação para a Ciência e a Tecnologia through the Grant: UIDB/00447/2020 attributed to CIPER–Centro Interdisciplinar de Estudo da Performance Humana (unit 447) (DOI: 10 .54499/UIDB/00447/2020) and by European Commission by Wage: Healthy working environments for all ages: an evidence-driven framework (Grant agreement ID 101137207).